High-Performance Coatings for Prepainted Insulated Metal Panels

Prepainted IMPs Offer Energy Efficiency and Durability

Architects and building owners continue to use prepainted metal for its ability to deliver long-term durability in terms of chalk, fade and adhesion. Similarly, the use of Insulated Metal Panels (IMPs) is on the rise in a variety of roof and wall applications due to its sustainability and versatility as a building product. Combining the two, prepainted IMPs achieve superior energy efficiency and durability, both of which are necessary to contend in today’s competitive marketplace and comply with ever-evolving, and increasingly demanding building codes.

IMPs Offer Many Design Options

Prepainted IMPs provide architects the ability to create unique designs free of restriction with multiple profiles, colors, reveals and custom modular widths, resulting in aesthetically pleasing design options for horizontal and vertical applications. The coil coating process offers engineered paint systems for a wide variety of applications that also provide excellent flexibility and hardness that can be formed into a prepainted finished product with performance characteristics superior to post-painted metal.

The Coil Coating Process Ensures High Performance and Durability

Prepainted metal is appealing for many reasons, including the consistent quality of the paint finish, manufacturing efficiency and speed to market.

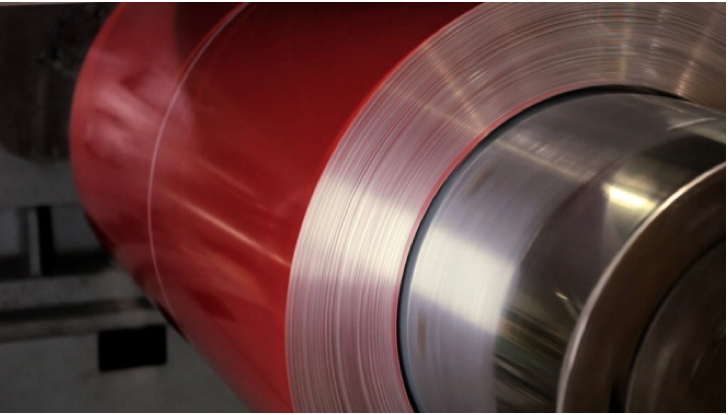

During the continuous coil coating process, metal coils are unwound, cleaned, pretreated and coatings are roll-applied with controlled and uniformly thick applications of primer and finish coatings. This process results in very consistent coverage across the entire coil. This method is highly efficient and unmatched by metal components painted after fabrication.

Prepainted metal is designed to withstand harsh weather and provide excellent corrosion resistance. With prepainted metal, pretreatment and multiple coatings are applied to both sides of the metal to enhance its long-term durability. The continuous coil coating process uses a closed-loop thermal oxidation system, which captures and destroys volatile organic compounds (VOCs) found in solvent-based coil coatings. The waste heat is then returned to the ovens to reduce or eliminate the need for natural gas consumption, making the coil coating process environmentally friendly. On average, a continuous coil coating line takes 15 minutes or less to process coils that weigh 20,000 to 60,000 pounds, increasing manufacturing output and satisfying demand more efficiently.

Benefits of Insulated Metal Panels

IMPs are considered the ultimate solution for the architectural, commercial, industrial, cold storage and residential markets due to their excellent insulating and weatherproofing characteristics. IMPs have a continuous insulating foam core that is formed together between two sheets of coated metal to provide resistance to air, moisture and thermal transfer conditions for increased building envelope performance.

The IMPs performance level can be precisely measured and is expressed in R-values which is the measurement of the effectiveness of insulation and its ability to resist heat flow. The higher the R-value, the more effective the insulation. IMPs, with their prepainted metal facings, have an R-value of R-7.0- to 7.2-per-inch, whereas unfaced urethane has an R-value of only R-5.6-per-inch. This superior insulation performance mitigates thermal bridging and thermal drift. Due to these high insulating capabilities, less insulation space is required to comply with building codes, leading to maximized enclosed space.

Because of the vast coatings available, IMPs are adaptable for substitution or use with many other building materials, including tilt-up concrete, stucco, brick, block, single skin metal panels, glazing and Exterior Insulation and Finishing Systems (EIFS).